How Odoo Improves Supply Chain Management for Food and Beverage Companies

Published on November 18th 2025

Introduction

Why is the F&B industry still struggling with supply chain issues - even with better technology, smarter systems, and evolving industry practices?

In an industry where freshness expires faster than profits, visibility is everything; yet most brands still operate in the dark.

Every stage of the F&B chain—procurement, production, packaging, and delivery—feels the pressure. Demand changes overnight. Seasonal sourcing adds uncertainty. New safety rules appear every quarter. Between production, packaging, and last-mile delivery, a small delay in one area can ripple through the entire network.

For many companies, the root cause hasn’t changed in years: old systems held together by spreadsheets and manual checks. Inventory updates arrive late. Orders get confirmed twice. With data scattered across systems, teams often make decisions too late—or based on outdated information.

Enter Odoo ERP: a reliable platform that turns inefficiency into results throughout the F&B industry.

The software brings together procurement, manufacturing, and logistics on a single dashboard, enabling teams to collaborate and access real-time information.

In this blog, we'll discuss how Odoo makes it easier for food and beverage companies to track their product inventory, reduce waste, and speed up deliveries. Let's get going.

The Hidden Cost of Fragmented Supply Chains

When procurement, inventory, and logistics don’t communicate, things start slipping through the cracks.

Orders move, but no one sees the full picture: that’s where profit quietly disappears.

Disconnected systems create blind spots. Procurement over-orders to play it safe. Warehouses hold excess stock “just in case.” Logistics teams chase updates across spreadsheets. In the process, margins shrink, and working capital remains tied up in inventory.

Here’s what that looks like in real life:

A mid-size bakery brand running multiple outlets across cities. Flour demand is logged weekly, not daily. Forecasts are off by a small percentage every time. Insights suggest that the bakery is set to lose nearly 8% of its profit in expired raw materials and emergency purchases by the next quarter.

That’s the hidden cost of fragmentation: small inefficiencies that compound until they impact profits.

An integrated ERP like Odoo helps connect such hidden dots seamlessly. It aligns procurement, production, and delivery flow, turning supply chain chaos into controlled movement and measurable savings.

Interestingly, when Odoo is implemented by experts at Uncanny Consulting, there are more ways in which Odoo can add to your operations. Let us now understand how Odoo enables this through its modules.

4 Core Odoo Modules That Transform Supply Chain Operations

Having a supply chain that runs on disconnected systems is like running your business without a proper direction. You might move fast, but you’re not in control. Odoo fixes that by aligning every department (procurement, inventory, production, and delivery) towards your company’s vision and goals.

Here are some core Odoo modules that transform supply chain operations:

Inventory & Warehouse Management

If you’re dealing with perishable items, expiry mistakes cost real money. Odoo handles batch and expiry tracking automatically, so there’s no surprise later. Stock moves follow FIFO or FEFO, keeping goods fresh without manual checks. What’s more? By implementing a dedicated inventory management barcode system, you can trace items from storage to shipment with total precision—eliminating clipboards and manual entry confusion entirely.Procurement & Supplier Management

Running low? The system creates purchase orders before it becomes a problem. It compares supplier performance, checks pricing, and logs quality for every batch received. Over time, that builds a record of which vendor really delivers.Manufacturing (Production Planning)

For FMCG brands, the ingredients matter. The Bill of Materials in Odoo locks in the right mix, batch after batch. You can plan output for rush seasons and, with IoT sensors, keep equipment checked in real time. Implementing odoo erp for food & beverage manufacturing ensures that these automated production schedules are fully integrated with your quality control and compliance standards, preventing downtime before it startsLogistics & Distribution

Ever wanted a system that aligns routes, drivers, and warehouse locations, connected over a single dashboard? Odoo maps deliveries, tracks cold-chain data, and syncs with third-party logistics. Drivers get mobile dashboards showing routes, delivery status, and proof of delivery updates — keeping your operations simple, visible, and efficient.With Odoo, you don’t just automate operations, you align them for maximum performance. That’s where the friction between supply chains converts into one clean motion.

Ensuring Food Safety with Odoo’s Traceability & Compliance Tools

In food manufacturing, mistakes don’t just cost money; they cost customers to your business.

That’s why tracking your workflow isn’t optional anymore; it’s the backbone of trust.

Real World Case Study

A beverage brand switched to Odoo for production traceability. The brand faced a challenge tracking the source of its products. Here, Odoo helped them with the following:

Complete Tracking Ability

Odoo allowed the beverage brand to track every ingredient, from supplier to shelf. Its end-to-end tracking further connected purchase orders, batches, and production over a singular dashboard. This way, the production managers would be able to isolate singular batches (in case of a production issue) rather than putting the entire product line on hold.Streamlined Compliance

Odoo helped the beverage business streamline compliance across different authorities for regional sales. The brand achieved full compliance with FSSAI, FDA, and HACCP requirements, as Odoo automatically logged every audit trail (temperature checks, expiry records, quality approvals), all in a digital, accessible formatWithin a quarter, their recall processing time dropped by 70%. Less paperwork, faster response, more confidence from retailers.

Uncanny Note:

“When you can trace every step of production, compliance becomes simpler and recalls get faster.”

The more transparent your process is, the stronger your reputation when something goes wrong.

Future Forecasts Meet Efficient Production

Every production manager knows this: if sales and inventory are out of sync, waste piles up fast. Here’s Odoo’s role in demand forecasting:

- Access to projections: Odoo doesn’t just project numbers; it reads patterns: seasonal, regional, even sudden spikes. As a business owner, you have access to data that helps prepare for production spikes in advance. For example, Odoo forecasts the increase in production before the winter holidays, allowing businesses to meet new demands.

- Real-time data: Sales data flows straight into production planning. No separate sheets, no chasing updates. When one region heats up, the system automatically adjusts its output.

Real World Case Study

Before implementing Odoo, a snack company was facing difficulties in managing ideal inventory for its business. It used to deal with excessive stock or stockouts due to fluctuating demand. They solved it with Odoo demand forecasting, which cut down on the waste of raw materials and helped them reach out to 22% new customers.

That's the hidden strength of future forecasts. It removes guesswork and last-minute chaos—helping your production team operate with consistent speed and accuracy..

Where Odoo Becomes A Game Changer for F&B Industries

Quality Control as A Continuous Loop

In Odoo, QC points are present at every step, from procuring raw materials to dispatch. If something’s off (temperature, label, weight), the system auto-flags it and alerts the team in real time.Every check builds a digital trail. So when the audit comes, you’re ready: clean records, zero chaos

Uncanny Note

“With Odoo + Uncanny, quality control becomes a culture, not a cost.”

Real-Time Visibility = Faster Decisions

You can’t fix what you can’t see. Odoo makes visibility routine, not a report request. Dashboards show live data across production and logistics, all in sync.Procurement heads see supplier delays. Ops managers track daily output. Finance spots cost drifts before they hit P&L. Even during production, a quick glance at a mobile device tells teams what’s moving and what’s not.

Uncanny Insight

“You can’t improve what you can’t see; visibility is where efficiency starts.”

The Cost Advantage: Where Odoo Saves the F&B Industry Millions

Every dollar spent on food and beverage runs tight. Margins are thin, shelf lives are shorter, and inefficiency shows up fast. Odoo changes that by connecting the dots that most systems leave scattered. By optimizing your Odoo supply chain for F&B you can turn fragmented data into real-time insights, allowing you to reduce waste, manage expiration dates proactively, and protect your bottom line in an increasingly competitive market.

| Area | Legacy Tools | Uncanny’s Odoo Implementation |

|---|---|---|

| Inventory Holding | 25–30% excess stock | Reduced by 20% with forecasting |

| Manual Errors | Increased rework and spoilage | Reduced 80% through automation |

| Compliance | Delays and penalties | Zero missed audits with digital tracking |

| Production Downtime | Frequent, reactive | Predictive and planned |

Case Study Snapshot: How an FMCG Brand Gained Predictive Control

The Problem

Every three months, a fast-moving consumer products brand loses about 12% of its stock. Procurement ran on email, manufacturing lagged sales data, and dispatch teams were constantly trying to catch up.

The Solution

Uncanny leveraged Odoo's Inventory, Purchase, and Manufacturing modules. The new structure ensured that the flow of raw materials, batch planning, and shipment timetables worked together in real time.

The Outcome

In four months, delivery improved by 40%, waste decreased by 30%, and losses from expiration were almost eliminated.

“We stopped reacting to supply issues, we started anticipating them.”

That single shift (from reaction to prediction) turned a leaking process into a profitable rhythm.

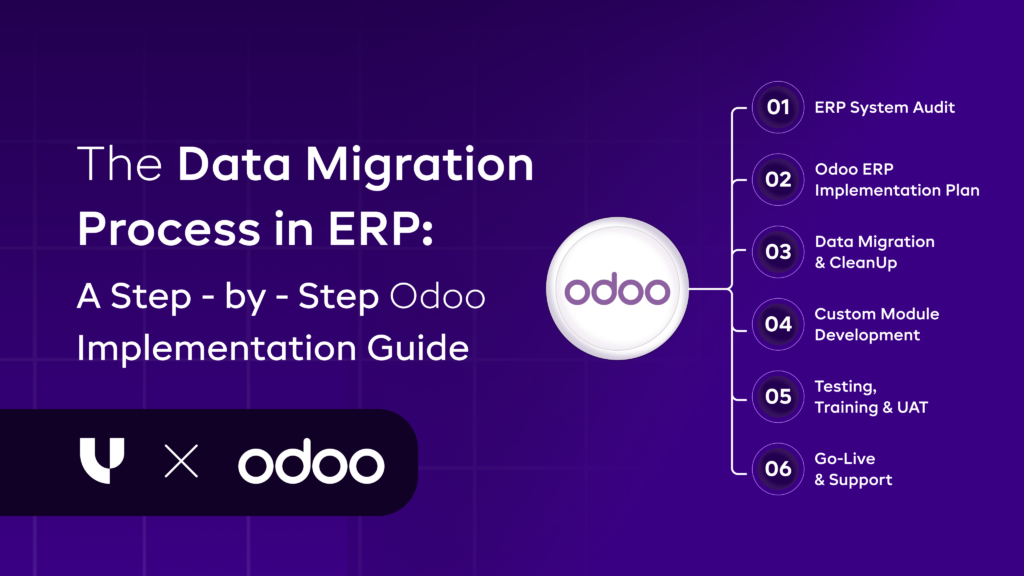

Implementation Roadmap: Getting Odoo Right the First Time

Rolling out Odoo across a supply chain takes time and precision. It’s not about pressing “install,” it’s about understanding how people, products, and data already move through your business. The smoother the understanding, the better the system fits.

Let’s take a closer look at the implementation roadmap for Odoo:

Step 1: Process mapping and audit

At Uncanny, we start the implementation process by examining your workflow. We examine every section: How do purchase orders flow? Where do delays usually start? Which tasks still depend on manual updates? Once that picture is clear, we know how Odoo should be shaped around it.

Step 2: Phased rollout (procurement → inventory → logistics)

Instead of switching everything at once, each stage gets its own focus. Procurement first, then inventory, then logistics. This way, teams learn as they go and small fixes happen before they grow into big ones.

Step 3: Staff onboarding and mobile training

Technology works only when the people using it are confident. Hands-on sessions and short mobile demos help staff become comfortable recording data, checking stock, and updating dispatches right from the floor.

Step 4: Post-implementation review

After launch, we keep checking. Are reports accurate? Are approvals slower or faster? Small tweaks at this stage make a big difference later.

Uncanny Consulting Insight:

Our Odoo-certified experts have helped food and beverage brands move from guesswork to clear, predictable operations. That’s where the real improvement starts.

Your Supply Chain Deserves Better Than Spreadsheets

Move from manual tracking to a smart, connected Odoo ERP system that reduces waste, delays, and compliance headaches. Uncanny can make that happen for you.

Get a Demo of Odoo ERP

Transform Your Supply Chain from Reactive to Predictive with Uncanny + Odoo

In today’s F&B industry, freshness doesn’t wait—and neither should your systems. Odoo gives you the visibility, traceability, and control to keep every batch, order, and delivery moving smoothly.

But technology is only as good as its implementation. That’s where Uncanny steps in.

Our Odoo-certified experts don’t just “install software”—we shape it around how your F&B business actually runs. From ingredient sourcing to shelf delivery, we help you replace guesswork with data-backed decisions and build a supply chain that runs predictively, not reactively.

So, if you’re ready to make freshness measurable and efficiency your new standard, let’s build it together — with Odoo + Uncanny at the core.

Talk to our Odoo experts today to get started.

FAQs

Q. How does Odoo give better visibility in the food and beverage supply chain?

Most plants deal with scattered reports: stock in one sheet, purchase in another. Odoo simply brings it all together. You can trace a batch from supplier to shelf, watch material flow in real time, and catch delays early. Managers stop guessing and start planning with data that’s live, not outdated.

Q. Can Odoo really help cut waste and control ingredient costs?

It can, and that’s where most brands see quick returns. Because Odoo reads patterns, it warns you when stock is about to expire or when reorder levels are too high. That balance keeps waste down, especially in perishable lines like dairy or baked goods.

Q. How does Odoo make food safety compliance easier?

Compliance audits used to mean folders and panic. With Odoo, every ingredient, vendor, and dispatch carries its own digital record. During an inspection, you can show complete lot histories in seconds. With Odoo, your business aligns with different safety compliances, following the checklist everywhere.

Q. Does Odoo handle multi-stage production, like recipes or blending?

Yes. In food manufacturing, each step depends on the last. Odoo’s MRP sets up clear routes (mix, fill, label, pack) and tracks what goes where. When something changes, like a batch size or ingredient swap, the system adjusts downstream automatically. That’s real coordination, not chaos.

Q. How does it help coordinate with suppliers and distributors?

Most delays come from miscommunication. Odoo links everyone on one platform. Vendors see confirmed POs; distributors see what’s ready to move. No more chasing updates through WhatsApp or email chains. That visibility keeps the cold chain running smoother and the customer shelf always stocked.

About Author