Top 10 Reasons for ERP Implementation Failures: 2026 Edition for Organizations

Published on August 22nd 2025

Introduction

ERP failures continue to surface every year, despite countless guides, checklists, and ‘best practices.’

The real question isn’t why implementations fail. It’s why the same failures keep repeating.

The truth is, an ERP implementation is one of the most demanding activities your organization will ever undertake. It touches every team, every process, and every system you rely on. When it goes right, it becomes the nervous system of your business - decisions get sharper, operations flow better, and teams finally work on one unified vision.

But when it goes wrong?

You feel it everywhere with missed deadlines, unpredictable costs, frustrated users, broken workflows, and months (sometimes years) of lost progress.

And the most important part that no one likes to admit - most ERP failures are never a surprise.

Before implementation begins, organizations must understand ERP stages—evaluation, selection, planning, configuration, testing, deployment, and stabilization. Missing even one stage creates cracks that lead to predictable failure.

Organizations, even well-funded ones, fall into the same traps repeatedly. If you understand these failure patterns before you start your ERP implementation, you can avoid the missteps.

To ground this conversation in reality and help you see how these failure patterns unfold within an organization, we’ve included a real-world case study from our 2025 ERP implementation. It illustrates where ERP programs typically break, and how the right structure prevents those missteps as we move into 2026 and beyond.

How to build a Future-Ready ERP Foundation: For example, a US-based Electric Component Manufacturer

Consider a mid-size US-based electric component manufacturer preparing for a period of expansion that requires stronger operational alignment, clearer data visibility across teams, and systems that can support the pace of 2026 and beyond.

Suppose their previous tools have reached their limits, and leadership wanted to implement an ERP that would remain a reliable ERP choice as their business scaled.

From day one, we might approach the implementation with one objective:

- Eliminate every predictable failure pattern before it can take shape.

- Every step, starting from planning to keeping the data ready for implementation to team

involvement, is designed to strengthen the foundation and reduce risk early.

Here’s how the path of the implementation looks, and how to avoid the top 10 failure reasons that organizations continue to encounter, even with required resources and strong intent in place.

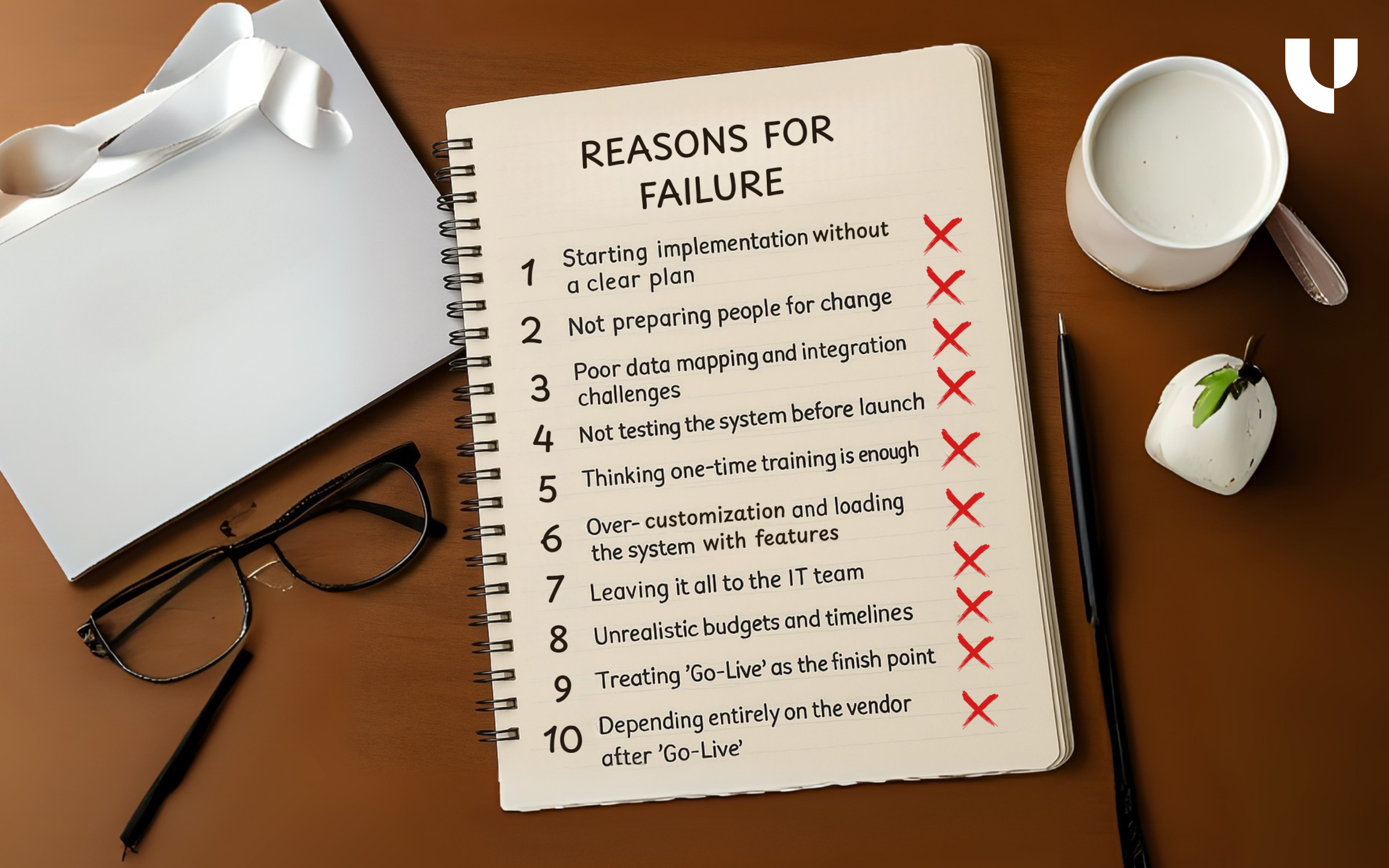

10 ERP Reasons of ERP Implementation Failures: Answering Your Question ‘Why Do ERP Implementations Fail’

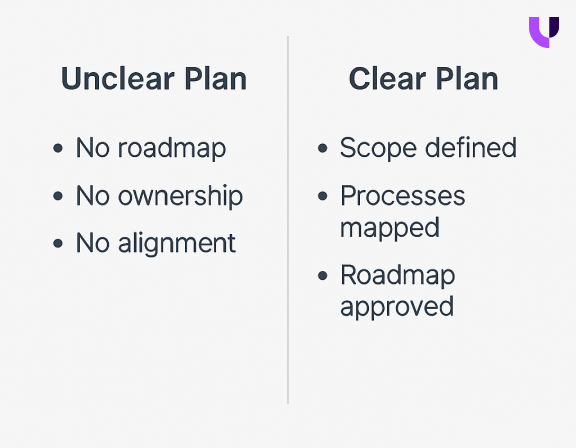

1. Starting Implementation Without a Clear Plan

ERP projects often begin with momentum but lack structured planning. Without defined priorities, scope, or process clarity, your teams are bound to move in different directions.

ERP projects often begin with momentum but lack structured planning. Without defined priorities, scope, or process clarity, your teams are bound to move in different directions.

How would we approach?

We will spend the initial phase aligning leadership, reviewing core ERP modules the electric component manufacturer needs, mapping cross-functional processes, defining non-negotiables, and building a phased roadmap that guides every decision.

This clarity will ensure the implementation stays aligned with business goals and remains predictable

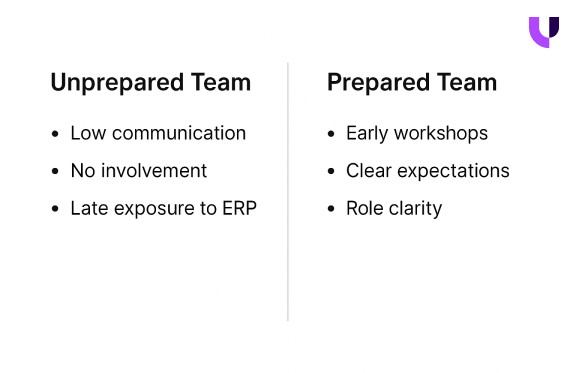

2. Not Preparing the Team for the Change

Most ERP failures are because the team is unaware of change, and not technology changes. When teams are not prepared for new processes, responsibilities, and workflows, resistance builds quietly and adoption delays. A proactive approach is necessary to ensure that employees don't feel sidelined during the transition.

How would we approach?

We will bring the actual users from the manufacturer's team into the process, with timely workshops, previews, and department-level discussions. By involving them from the start, we reduce uncertainty and build confidence among the teams. A critical part of this strategy is using an ERP implementation partner to guide the cultural shift, ensuring the workforce is ready for Go-Live and fully understands the "why" behind the new system.

3. Poor Data Mapping and Integration Challenges

Your ERP environments fail when data is inconsistent, duplicated, or structured differently across systems. Broken integrations and unreliable reports quickly lose the trust of your stakeholders, including the loyal customers.

Your ERP environments fail when data is inconsistent, duplicated, or structured differently across systems. Broken integrations and unreliable reports quickly lose the trust of your stakeholders, including the loyal customers.

This is also where ERP features matter—data standardization, integration connectors, audit trails, and unified data models. Understanding these features early helps avoid mapping failures later.

How would we approach?

Before configuration begins, we validate their entire data landscape, clean legacy records, standardize field names, and run early integration tests. This eliminates downstream issues and provides the electric component manufacturer with a clean data foundation for the future.

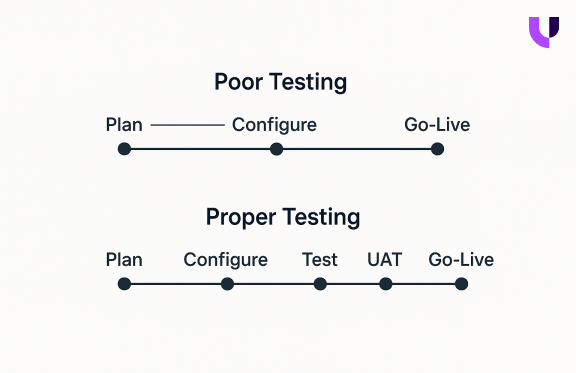

4. Not Testing the System Before Launch

When testing is rushed or not prioritized, issues only surface during your real operations. It actually disrupts everything from order flows to financial records.

When testing is rushed or not prioritized, issues only surface during your real operations. It actually disrupts everything from order flows to financial records.

How would we approach?

We build multiple test cycles into the project plan: functional testing, scenario-based testing, and full workflow simulations. By the time the component manufacturer’s system goes live, the system has already been tested against real-world usage patterns.

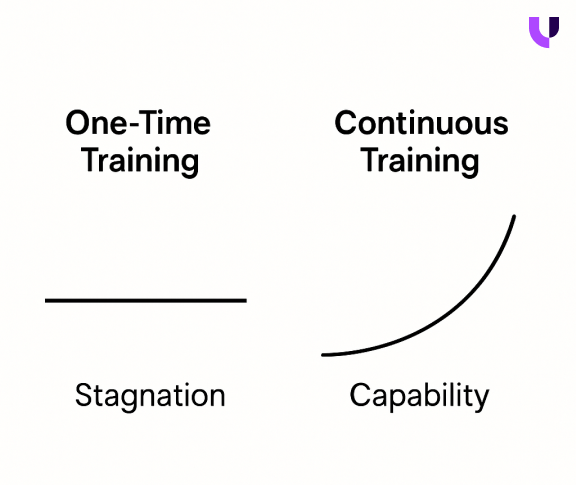

5. Thinking One-Time Training Is Enough

One-session training creates familiarity, but it may not make your team capable of using the new system. Without reinforcement, teams are likely to fall back on old habits.

One-session training creates familiarity, but it may not make your team capable of using the new system. Without reinforcement, teams are likely to fall back on old habits.

How would we approach?

We create a layered enablement model that spans foundational training, role-based deep dives, post-Go-Live guidance, and easily accessible documentation. This will ensure long-term competence, avoiding short-term exposure.

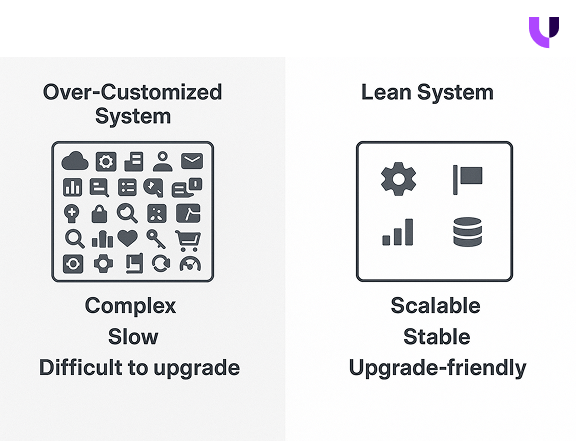

6. Over-Customization and Loading the System With Features

ERP implementations fail when leadership is focused on adding existing and new features, overloading the system. It creates complexity for your team and technical debt.

ERP implementations fail when leadership is focused on adding existing and new features, overloading the system. It creates complexity for your team and technical debt.

How would we approach?

We adopt a “configuration-first” approach. Customizations are approved only when they create measurable value. By keeping the system clean and intentional, the electric component manufacturer will be ready to enter any competitive market today or tomorrow with an ERP that is scalable and upgrade-friendly.

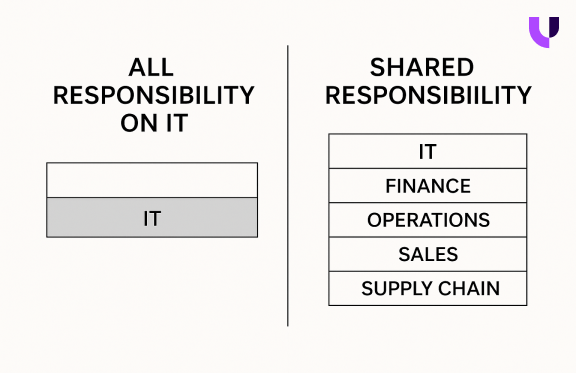

7. Leaving It All to the IT Team

ERP becomes unstable when your teams disengage and IT becomes the sole decision-maker. Context is lost, processes misalign, and ownership weakens.

ERP becomes unstable when your teams disengage and IT becomes the sole decision-maker. Context is lost, processes misalign, and ownership weakens.

How would we approach?

We ensure co-ownership. Finance, operations, sales, procurement, and compliance leaders of the component manufacturer will be asked to be involved in every process decision. IT provides structure, but the business shapes the system.

8. Unrealistic Timelines & Budgets

Shortened timelines and tight budgets force your ERP implementation partners to skip planning, data cleanup, and training, leading to long-term rework and instability.

Shortened timelines and tight budgets force your ERP implementation partners to skip planning, data cleanup, and training, leading to long-term rework and instability.

How would we approach?

We create a phased timeline aligned with operational cycles and set a realistic budget that accounts for data, change management, and training. This will help the electric component manufacturer to avoid the rushed compromises that weaken ERP foundations.

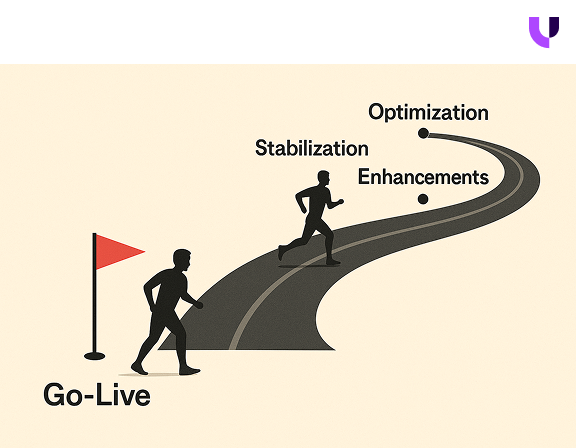

9. Treating “Go-Live” as the Finish Point

ERP value isn’t realized at launch. It’s discovered in the months that follow. Organizations that stop investing after Go-Live never unlock the system’s full potential.

ERP value isn’t realized at launch. It’s discovered in the months that follow. Organizations that stop investing after Go-Live never unlock the system’s full potential.

How would we approach?

We treat Go-Live as the transition point. Post-launch audits, refinement cycles, and performance checkpoints ensure the system remains mature.

10. Depending Entirely on the Vendor After Go-Live

Many businesses using ERP ask how long they need to be dependent on ERP consultants. Gradually, after implementation, vendor reliance for everything slows your growth, complicates decision-making, and prevents your team from owning its ERP.

How would we approach?

We build internal capability through admin training, process documentation, governance guidelines, and self-service tools. We will ensure that the manufacturer’s team is fully capable of operating and improving the system independently.

Want to start a project with us?

Empowering businesses to achieve greatness through strategic guidance and innovative solutions.

Book A Demo

Leadership Debrief: What Hershey’s $100M ERP Breakdown Still Teaches Us

Even though Hershey’s ERP failure occurred decades ago, it remains one of the clearest demonstrations of how leadership decisions determine ERP outcomes. And as we move into 2026, the core lessons remain unchanged because the failure patterns remain unchanged.

Where Hershey’s Went Wrong (And Why ERP Failures Still Repeat Today)

1. Insufficient Testing

Hershey’s compressed its timeline from 48 months to 30, eliminating critical testing cycles, a mistake modern organizations still repeat in an effort to “go-live quickly.”

2. Inadequate User Training

Employees weren’t equipped to use the system. Today, this is still one of the leading causes of post–go-live instability.

3. Poor Go-Live Timing

Deploying during peak seasons created operational bottlenecks. In 2026, we think there is a higher risk in complex integrations and real-time demand fluctuations.

Rushed Timeline Under External Pressure

The Y2K deadline accelerated decisions and cut corners; much like organizations today rush to meet investor pressure, enter expansion cycles, or close financial years

What was the impact of ERP implementation failure?

- $100M lost sales

- 19% drop in quarterly profits

- 8% decline in stock price

- Recovery costs that exceeded initial project budgets

Leadership Takeaway for 2026

The most significant lesson we learned from Hershey’s failure, and we take with us for 2026, is that readiness determines outcomes.

System, business, and people readiness must converge before go-live. Leaders who enforce this alignment avoid the exact ERP failures that cost Hershey’s millions.

Conclusion: ERP Success is a Leadership Discipline

If there’s one takeaway for 2026, it’s this: ERP doesn’t reward speed; it rewards discipline.

The organizations that thrive aren’t the ones that implement the fastest; they’re the ones that build clarity early, involve the right people from the initial phase, test rigorously, and treat Go-Live as the beginning of operational maturity.

When leadership sets the tone and the ERP implementation partner brings structure, ERP becomes an asset that grows with your growing business, and not a risk you have to manage.

The path to ERP success is straightforward.

‘The commitment to follow it is what makes the difference.’

FAQs: What every decision maker asks about ERP failures?

How do we know our ERP implementation timeline is realistic for 2026?

A timeline is realistic only if it accommodates three non-negotiables: testing cycles, structured training, and phased rollouts.

If any of these are compressed to “make the date,” the timeline is not ready.

ERP programs span 12–36 months, depending on process complexity, integrations, and data readiness.

What is the #1 early sign of ERP implementation failure?

If your employees - the people who are supposed to use the ERP - start going back to spreadsheets or finding shortcuts during the pilot phase, it’s a clear sign: adoption is in trouble, and so is your project.

Can ERP failures be reversed, or do companies have to start over?

Most ERP failures don’t require starting over. With the right stabilization program of targeted training, data cleanup, and phased reimplementation of broken workflows, businesses can recover. The key is early leadership intervention before issues become irreversible.

Why do data mapping issues cause so much disruption during ERP implementation?

Data inconsistencies surface during transactions. Incorrect field mapping, duplicate records, and unaligned structures break integrations, corrupt reports, and slow down operations.

Organizations preparing for 2026 and beyond must prioritize data architecture validation early and not treat it as a pre-Go-Live activity.

We’re a startup. Do the same ERP failure patterns apply to us?

Yes, and sometimes even more strongly.

Startups often rush implementation to support growth, but without transparent processes, clear ownership, or data hygiene, the ERP becomes a bottleneck rather than an accelerator.

What should UK companies be most careful about with ERP implementations in 2026?

UK organizations face additional challenges around compliance, tax updates, and multi-entity operations post-Brexit.

The most significant risk is misaligned regulatory mapping, especially for VAT, cross-border trade rules, and inventory traceability.

Testing for financial accuracy is essential, and not optional.

What ERP failure risks are unique for Australia & New Zealand?

ANZ organizations often operate across dispersed geographies and rely heavily on field operations, logistics, and inventory movement.

The most significant failure points are:

- Inaccurate demand forecasting

- Weak offline/remote capability

- Integrations that can’t support distance-based delays

- Insufficient training for regional teams

ERP implementation must be designed for distributed work, and not just headquarters. Get in touch with us for a detailed understanding.

Are there ERP Implementation risks for Russia or CIS region companies?

Yes — especially around localization and compliance.

Common failure points are:

- Incorrect mapping of tax codes

- Weak localization support

- Limited alignment with Russian accounting norms

- Dependency on systems that do not integrate with existing local financial tools

Localization accuracy becomes the deciding factor between ERP implementation stability and failure in Russia and the CIS region.

About Author