Odoo ERP for Food And Beverage Businesses: Your Guide To Efficiency And Growth

Published on September 23rd 2025

Introduction

Running a food or beverage business means your day is never quiet. One moment you’re checking on suppliers, the next you’re managing production, watching expiry dates, dealing with your staff, or handling orders from different channels. With information scattered across spreadsheets, a separate POS, and accounting tools that don’t show what’s actually happening on the floor, simple decisions will start giving you a feeling of being complicated.

Odoo ERP helps bring everything into one place. It connects your purchasing, stock, production, quality checks, sales, and finance, so teams don’t have to chase information or rely on guesswork. In this guide, we’ll walk through how Odoo aligns with how real F&B businesses operate, which modules matter, the everyday issues it solves, and how Uncanny sets it up to match your actual processes

Why Food And Beverage Companies Are Paying Attention To Odoo ERP

Food and beverage is a demanding industry with thin margins and little room for error. Many teams start with basic tools, but eventually they outgrow them.

Here are a few reasons why more food and beverage businesses are exploring Odoo.

Odoo lets you start small and grow at your own pace

You can begin with just the essential modules, such as inventory, sales, and accounting, while you stabilize the basics. Once the team is comfortable, you can gradually add other modules such as manufacturing, POS, quality, HR, and marketing, rather than turning everything upside down on day one.

Odoo fits different food and beverage business models on one platform

Whether you run a bakery, a craft brewery, a central kitchen, a distribution setup, or a retail chain, Odoo can be tailored to match how you actually work. This means you can keep one core system even if you expand into new products or formats later.

Odoo feels simple enough for your team to use

The Odoo screens look like modern business tools rather than old technical software, so that most people can pick up the basics quickly. This reduces training effort and increases the likelihood that staff will use Odoo effectively, rather than reverting to spreadsheets.

Odoo can be tailored to your recipes and processes

You can adapt Odoo to your own recipes, production steps, approvals, and reports rather than forcing your business into a rigid template. When the design is clear, every change remains easy to follow, and nothing becomes random, hard-to-maintain tweaks.

6 Key Challenges Food And Beverage Teams Deal With Every Day

Before getting into particular Odoo modules, it’s important to understand the real problems happening in the background. We see these patterns across most food and beverage projects.

Supply chains that are complex and always changing

Food and beverage businesses hardly have a clear supply chain. There are processes being changed, backup plans, and last-minute adjustments that do not show up in a spreadsheet.

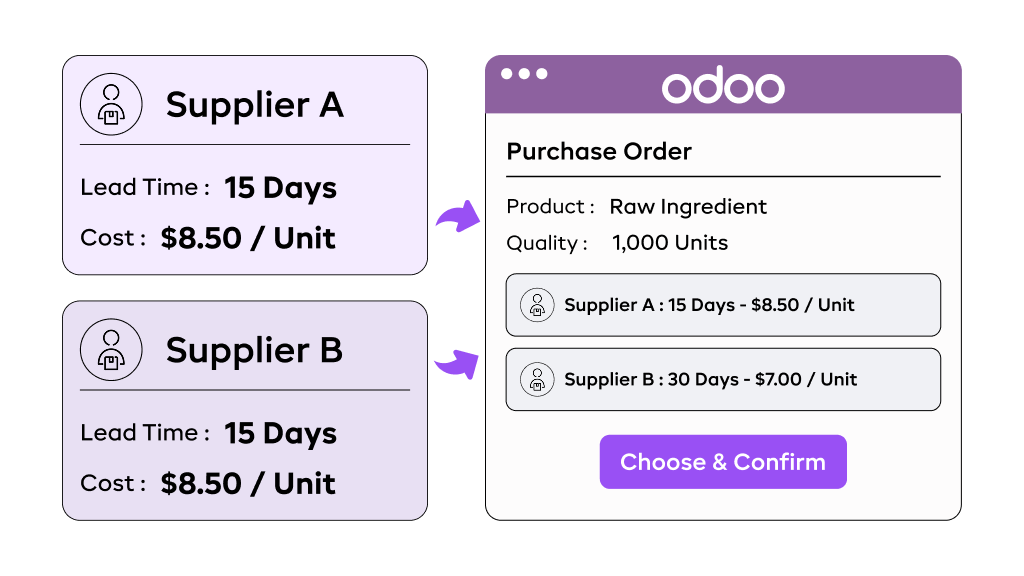

Working with more than one supplier for the same ingredient

Many companies keep two or three suppliers for the same ingredient. One may offer a better price, another may be more reliable, and a third may be kept as a backup for emergencies. When this is managed through emails or details are stored limited to a person, it becomes hard to remember the actual price, who can deliver the fastest, and which supplier is actually performing well.Lead times and seasonal items that keep changing

Imported spices, seasonal fruits, or specialty ingredients rarely follow a predictable pattern. Some containers arrive earlier than promised, while others are delayed. If you plan production based on assumptions rather than real purchase and stock data, you risk either stopping production or carrying too much safety stock.How Odoo helps in such situations

In Odoo, every supplier sits in one place along with prices, lead times, and past performance. Reordering rules combine this information with real-time stock and open orders.For example, a juice manufacturer can see that mango pulp from Supplier A has a longer lead time but fewer quality issues, while Supplier B is faster but more expensive. The planner can decide based on facts, not guesswork, and Odoo suggests purchase orders that reflect those choices.

Uncanny insight

In our projects, we usually begin by cleaning supplier and product data before switching on automatic reordering. This gives planners confidence that when Odoo suggests a purchase, it is based on information they trust rather than legacy records. For a deeper dive, read our post on how Odoo improves supply-chain management for F&B.

Compliance and food safety that you must adhere to

In food safety, it’s not enough to just follow the rules. You must be able to prove the safety of your food.

When something goes wrong, handwritten logs, spreadsheets, and scattered documents cannot protect you. Only clear, reliable records can.

Meeting traceability expectations in real life

Large retailers, export customers, and regulators expect clear traceability. They want to know which farm or supplier the ingredient came from, which production batch used it, and which customers received that batch. If this information is spread across delivery notes, emails, and Excel sheets, answering even simple questions can take days.Handling audits and recalls without panic

In a real incident, you often have only a few hours to act. If you can’t trace which lots are affected, you either recall far more than necessary or risk leaving the wrong products in the market. Both outcomes are costly, and both put your reputation at risk. What you need is instant, accurate traceability so your decisions are based on facts.How Odoo helps in such situations

With Odoo, lots and batches are registered as soon as goods arrive. When a batch of tomato puree is used in production, Odoo records which finished products it went into. If later you learn that a specific lot from a supplier has an issue, you can pull a report that shows exactly which finished batches used that lot and where they were shipped. During audits, you can walk through the full chain instead of searching through files.Uncanny insight

At Uncanny, we set up Odoo for food clients, and pay special attention to how lots are created and used in day-to-day workflows. The goal is to make traceability automatic as people do their normal work instead of adding extra manual steps that staff will eventually skip.

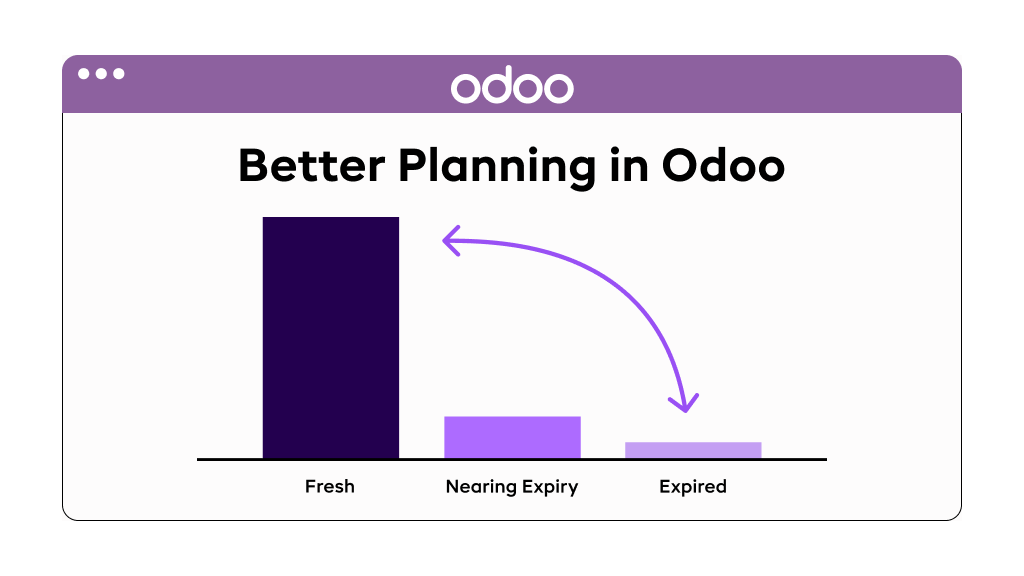

Perishable stock that make daily plannning a challenge

In this industry, products don’t stay fresh forever. They move toward expiry every hour. One miscalculated purchase can lead to stockouts, wastage, or unnecessary discounts. Precision in planning isn’t optional; it’s survival.

Overstocking that quietly eats your margin

When teams fear running out of stock, they often overorder to be safe. For perishable items such as fresh dairy, leafy vegetables, or short-life bakery ingredients, this can lead to regular write-offs. The cost may look small daily, but it adds up to a significant margin leak over a year.Understocking that hurts sales and relationships

On the other hand, buying too little or too late can stop a production run or force you to remove a product from the menu. Retail customers see empty shelves, restaurants do not receive their usual orders, and you may have to offer discounts or urgent air freight to recover. This affects both revenue and trust.How Odoo helps in such situations

Odoo allows you to record expiry dates for each lot and use FEFO, so the system suggests picking the items that will expire first. A central kitchen can see which vacuum-packed items must be used within the next two days and adjust production accordingly.Alerts help purchasing teams notice when certain ingredients need to be consumed or discounted before they are lost. Over time, you can compare planned with actual waste and adjust ordering rules based on real behaviour, not rough estimates.

To understand it with a real-world application, see how NAH Foods used Odoo for a 95% efficiency gain.

Quality and consistency that protect your brand

Customers may forgive a late delivery once, but they rarely forget a bad product experience. Consistent taste, appearance, and safety are what keep them coming back.

Quality checks that sit outside your main systems

Many teams still use clipboards or separate spreadsheets to record quality checks at goods receipt and during production. These records are easy to misplace and hard to analyze. When a customer complaint arrives, tracing the relevant checks takes a lot of manual digging.Recurring issues that stay hidden for too long

If quality data is not structured, it is difficult to notice patterns. You might not realize that most recurring issues come from one supplier, or that a particular issue is leading to most packaging faults. Without this insight, teams end up treating symptoms rather than causes.How Odoo helps in such situations

With Odoo, quality checks are triggered as part of the workflow. For example, every incoming batch of milk can automatically create a quality check task that requires specific measurements, such as temperature and acidity, before the lot can be moved to usable stock.If there is a recurring problem with one supplier, you can see a history of non-conformities linked to that supplier and that ingredient. A snack manufacturer can use these reports in supplier reviews to improve internal procedures.

Recipes and batches that keep evolving

Recipes in food and beverage are living documents. They change as you refine your product, respond to raw material changes, or adjust to cost pressures.

Recipes that change as your product improves

Over time, you might reduce sugar content, replace an imported spice with a local alternative, or change a cooking step to improve texture. If these changes are not controlled, different teams may follow different versions of the same recipe, leading to inconsistent taste results.Batch sizes and yields that do not stay fixed

A test batch behaves very differently from full-scale production. Yield losses shift with raw material quality, cooking processes, trimming, and even the equipment used. If you don’t capture actual yields in a structured way, planners end up working on assumptions. That leads to wrong cost calculations and inaccurate material planning, which ripple across the entire operation.How Odoo helps in such situations

In Odoo Manufacturing, each finished product has a Bill of Materials (BoM) that represents the current approved recipe. When you change a recipe, you create a new version rather than overwrite the old one.For example, a sauce manufacturer can keep a history of recipes as they reduce salt or change herbs, while ensuring that production teams always see the latest approved version. Work orders allow operators to record actual output, so you can compare expected and real yields for each product and adjust planning or pricing based on evidence.

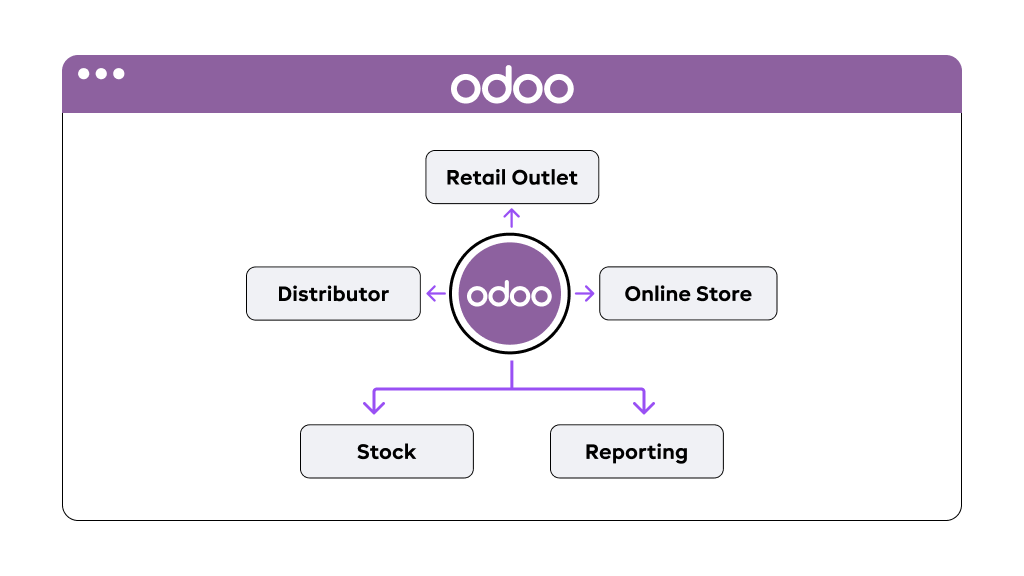

Multi-channel and multi-site sales that need a single view

Most modern food and beverage brands do not rely on a single channel for sales. They sell to B2B customers, run their own outlets, and sometimes sell direct to consumers online. Without a unified system, each channel becomes isolated.

B2B relationships with distributors and retailers

When you sell to distributors, supermarket chains, or hotel groups, you deal with volume-based pricing, promotional commitments, and credit limits. If these details live in separate files per salesperson, it is easy to make promises the operation team cannot fulfil or offer pricing that reduces margin.Direct sales through outlets and online channels

Cafe, brand stores, cloud kitchens, and ecommerce sites all need accurate stock and pricing. If your outlet POS, online store, and central inventory are not linked, you risk selling the same stock twice or disappointing customers with cancelled orders.How Odoo helps in such situations

Odoo connects every sales channel,POS and web app to a common inventory and accounting base. A brand that sells bottled cold brew coffee can see wholesale orders from retailers, retail sales through its own cafe, and online orders from the website in one dashboard.Stock reserves reflect confirmed orders across all channels, so planners know the real demand picture. This also makes it easier to compare profitability by channel and decide where to focus marketing and capacity.

How Odoo Fits Into A Typical Food And Beverage Workflow

To make this easier to understand, imagine you run a business that produces ready meals and sells them through retailers and your own outlets. Here is what your day-to-day workflow can look like when you use Odoo as your main system.

Your orders land in one place

Retailers send you purchase orders, your outlets request stock, and your online customers place orders. In Odoo, these all turn into sales orders, so you see total demand in one view instead of manually counting it together from different tools.

You plan production based on actual demand

You review confirmed orders and your safety stock levels, then create the production plan in Odoo. The system highlights your capacity and expected lead times so you do not schedule more than what the team and machines can handle.

You only buy what you really need

Odoo compares your planned production with the raw materials you already have. Wherever you are short, the system suggests purchase orders with recommended quantities and preferred suppliers. You decide what to confirm based on the real numbers.

You receive goods with traceability built in

When suppliers deliver, your warehouse team receives the goods into Odoo, records lot numbers, expiry dates, adds any relevant documents, and logs quality checks where needed. If something does not pass checks, you can stop that lot from being used before it enters production.

To get a better understanding of how Odoo helps you with warehouse management, click here.

You produce batches with clear records for every step

On the shop floor, operators open their work orders in Odoo, see which ingredients they should use, record what they actually consumed, and enter finished quantities and scrap. Quality checks that belong within the process appear as tasks against each batch, ensuring nothing is forgotten.

You store and reserve finished goods the right way

After packing a batch, your team moves it into the finished goods locations in Odoo. Every move carries the the lot and expiry details forward. When a sales order comes in, Odoo automatically reserves the stock that should go out first. Your rotation stays under control without manual tracking or separate lists.

You pick and ship orders with confidence

For each order, Odoo guides your warehouse staff to pick the right products and the right lots, following rules such as first expiry first out. When they validate the delivery, packing slips and delivery documents are created, and stock levels are updated straight away.

Your finance stays aligned without extra typing

After deliveries are confirmed, invoices are created from the same data and posted to accounting. Stock values update in the background, so your cost of goods sold and margins reflect what actually moved. You spend less time reconciling numbers between systems and more time reading reports that make sense.

With this setup, every step you take builds on the previous one inside a single system. You are not copying figures from one tool to another, and you always know where each order, batch, and shipment stands.

Want to start a project with us?

Empowering businesses to achieve greatness through strategic guidance and innovative solutions.

Book A Demo

The Odoo Apps That Usually Matter Most In Food And Beverage

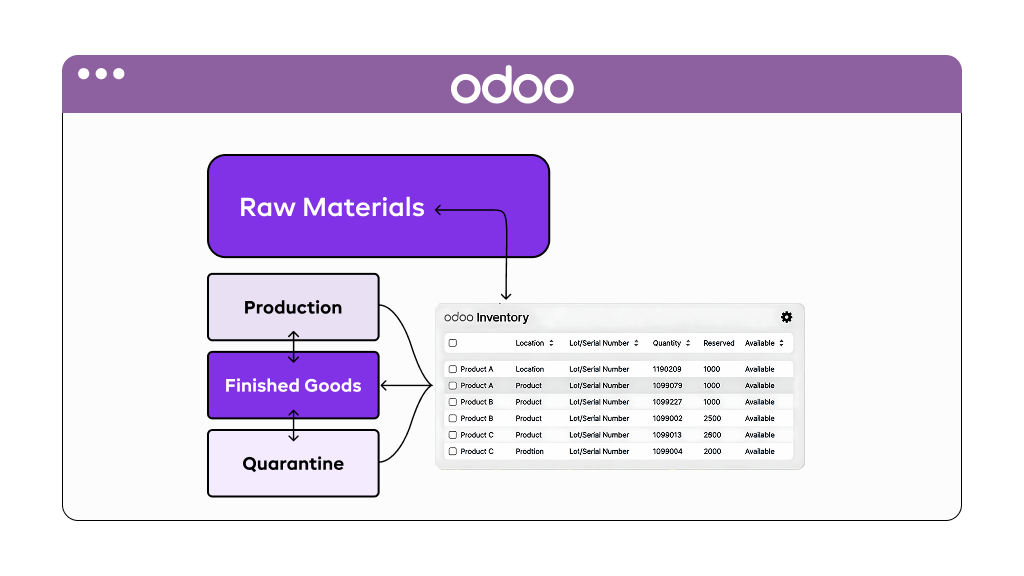

How the Odoo Inventory app becomes your base for stock and lots

Inventory is usually where your Odoo journey starts. If your stock is not right nothing else feels stable.

Real-time stock visibility

You can see how much you have by product lot and location across warehouses outlets and internal areas such as in transit quarantine or quality hold. This helps you plan production and deliveries without walking the floor or calling each warehouse.Lot and expiry tracking without extra spreadsheets

Lots are created or recorded when you receive goods and they stay with the product through production and shipping. Expiry dates are captured and can be used when you pick stock so the system nudges you to move the items that should go out first.Barcode and scanner friendly work

Your warehouse and production teams can use barcode scanners for receiving internal moves and picking. This reduces keying errors and makes day to day work faster which matters in cold rooms and busy docks.Uncanny note

We normally start by fixing product units and locations before going live with Inventory. Once your basic data is clean people start trusting what they see on screen and you can confidently move to more advanced features such as automatic reordering.

How the Odoo Manufacturing app mirrors your real production

If you cook, blend, brew, bake, or pack anything at scale, Manufacturing is where your recipes and processes become real digital flows.

Bills of Materials that act as living recipes

Each finished product can have a recipe that lists every ingredient quantity and by-product. You can keep this simple for basic products or very detailed for complex formulations. This connects raw materials directly to finished items so you always know what went where.Work orders that follow the way your team actually works

You can break production into steps such as preparation, mixing, cooking, cooling, and packing. Operators see these steps as work orders, record when they start and finish, and log any issues. This turns informal knowledge on the floor into structured information you can learn from.Comparing planned and actual performance

Odoo lets you capture actual material consumption and time spent per batch. When you compare this with what you planned, you can see where yields are lower or certain steps always take longer. That insight helps you adjust recipe instructions or staffing instead of assuming everything is on target.Uncanny note

When we configure manufacturing, we usually run a few pilot batches with your team inside Odoo. This lets operators tell us what feels natural and what does not, so the final setup reflects your real process rather than a textbook flow.

How the Odoo Quality app brings checks into your normal flow

Quality is most useful when it is part of your daily work, not an extra layer that people forget when things get busy.

Control points where they actually matter

You can decide that certain products or suppliers always require checks at goods receipt, and that specific production operations have their own in-process checks. Odoo then creates tasks automatically so people do not have to remember what to check and when.Flexible ways to record checks

A check can be a simple yes or no question, a numeric measurement, or a short form. For example, you might record temperature at receipt, visual checks during trimming, and seal integrity after packing, all in a way that suits each product.Using data to improve instead of just to file reports

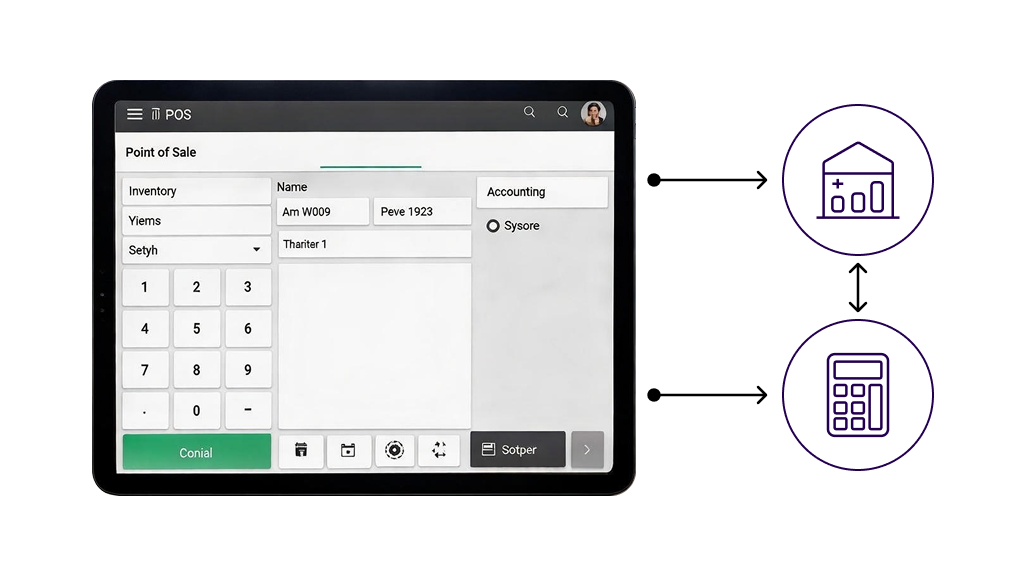

Because every check is stored in the same system that holds your lots, suppliers, and work orders, you can see patterns over time. You might notice that one supplier fails temperature checks more often or that a particular line produces more packaging issues, which gives you a clear starting point for improvement.How the Odoo Point of Sale app supports your outlets and tasting rooms

If you run cafés, shops, kiosks, or a taproom, your front-of-house needs to communicate with your back office without manual steps.

Simple screens for busy staff

The POS app is touch-friendly and supports product images and straightforward buttons. New staff can usually learn the basics in a short session, which helps during seasonal peaks or high turnover.Stock and accounting that stay in sync

Every sale through POS updates your stock and creates the accounting entries in the background. You do not need to export files at the end of the day and upload them somewhere else, which reduces end-of-shift stress and errors.Staying open even when the network has issues

POS can keep working if the internet drops and then sync with your main Odoo database once the connection returns. Your team keeps serving customers, and stock and financial data catch up automatically.

How the Odoo Sales and CRM apps support your B2B relationships

If you sell to retailers, hotels, restaurants, distributors, or other businesses, you need a structure around deal pricing and follow-up.

Keeping track of leads and opportunities

You can register new prospects, log calls, meetings, and samples, and see where each opportunity stands. This helps you and your sales team follow up at the right time instead of relying on memory or scattered notes.Quotes and agreements that flow straight into orders

Your team can prepare quotes with the right price lists and conditions and send them directly from Odoo. When a customer confirms, you can convert that quote into a sales order without retyping, which saves time and avoids mistakes.Understanding which customers and products drive your profit

Because Sales is linked with Inventory and Accounting, you can analyse sales and margin by customer, by region, and by product. This makes it easier to decide who should get more attention and which products need a different pricing or promotion strategy.How the Odoo Accounting app stays close to your real operations

Accounting in Odoo is not a separate island. It shares the same data your operations team uses which makes your numbers more trustworthy.

Automatic entries from day-to-day work

Customer invoices, vendor bills, and stock movements all generate accounting entries without extra typing. Your finance team spends less time entering data and more time checking and explaining results.Support for multiple entities and tax settings

If you have several legal entities or work with more than one tax regime, Odoo can handle that in a structured way. This is useful when you operate factories and sales companies in different regions or work both locally and for export.Financial reports that reflect what is happening now

Because Accounting pulls directly from live sales, purchase, and stock data, you can open profit and loss balance sheet and cash flow views that are much closer to real time. This helps you make faster decisions on spending, pricing, and investment.How the Odoo HR and payroll apps support complex staffing patterns

Food and beverage businesses often rely on shifts, weekend work, and seasonal hiring, so people data needs to be organised and accurate.

One place for employee information

You can keep contracts, roles, contact details, and important documents together for every employee, whether they work in production warehouses, sales outlets, or offices. This helps HR and managers stay aligned when staff move sites or change roles.Attendance and shift planning that match your operations

Odoo can track check-in and check-out times and handle shift schedules. This is useful when you run multiple lines or outlets and need to balance coverage while controlling overtime.Payroll that reflects actual hours and rules

When set up correctly, Odoo can use attendance data to help calculate payroll, including overtime and allowances. This reduces manual adjustments and disputes about hours and pay.How the Odoo Purchase app strengthens your work with suppliers

Purchase is where you turn your material needs into structured supplier orders and long-term relationships instead of last-minute calls.

Clear view of who supplies what and on what terms

For each ingredient or material, you can see approved suppliers' usual lead times, prices, and minimum order quantities. This lets buyers make decisions based on up-to-date information rather than old email threads.Approvals that protect your spend

You can require approvals for orders above certain values or for specific categories, such as new packaging or equipment. This helps control costs and ensures sensitive purchases are reviewed before money is committed.Supplier performance that you can actually measure

Over time, Odoo can show you which suppliers usually deliver on time, which tend to be late, and where quality issues start. That information is useful when you negotiate renewals or consider adding or removing suppliers from your list.Uncanny insight

We help clients set up simple supplier scorecards in Odoo, so your reviews are based on data such as delivery timeliness and quality results rather than impressions alone.

How the Odoo Marketing Automation app keeps you in touch with customers

If you sell direct or manage important customer portfolios, you need a consistent way to stay visible and relevant.

Segmenting customers in a meaningful way

You can group customers by location, purchase pattern, channel, or product interest. This lets you send focused messages, such as a new flavour launch to people who bought similar products before.Setting up useful automated journeys

You can create simple flows such as welcome messages for new wholesale customers, follow-up emails after first orders, or reminders when a product is likely to be finished at the customer's site. Once these are configured, Odoo runs them for you, and your team only needs to refine the content over time.Seeing what actually works in your communication

Odoo shows open rates, clicks and responses for each campaign. You can see which messages bring people back to order again and which do not move the needle and adjust your approach accordingly.Real Examples Of How Odoo Can Support Different Food And Beverage Models

To make the ideas more tangible, here are three typical setups and how Odoo can support them.

Craft brewery seeking control without heavy admin

A growing craft brewery often reaches a point where whiteboards and simple spreadsheets are no longer enough.

-

Production and recipe management

Odoo helps keep recipes organised, track ingredient consumption, and schedule brews. Each batch can be traced from raw materials to the keg or the bottle. -

Taproom and retail sales

Using POS, every sale in the taproom reduces stock. Sales data can show which beers move fastest in which periods. -

Distribution and wholesale

Sales and Inventory work together to manage orders from bars and shops and to avoid promising stock that is not available.

The brewery gains traceability, clearer planning, and a better understanding of which products and channels are truly profitable.

Soft drink distributor with multiple depots

A soft drink distributor has to keep many products moving through several warehouses.

-

Central order capture

Orders from retailers and field sales go into Odoo, giving a consolidated picture of demand across regions. -

Stock and route planning

Inventory and logistic features help assign stock from the right depot and plan deliveries more efficiently. -

Returnable packaging tracking

Returnable bottles or crates can be tracked with suitable configuration, reducing loss and disputes.

The distributor moves from reactive fire fighting to more predictable operations and service levels.

As we did for Moyee Coffee, we help F&B brands bring order, clarity, and control to their operations.

Central kitchen supplying several outlets

A brand that operates a central kitchen and several outlets needs coordination between production and retail.

-

Centralised production

The kitchen uses Manufacturing and Inventory to plan and produce items based on outlet forecasts and sales patterns. -

Distribution to outlets

Stock transfers are recorded in Odoo, and FEFO rules help ensure outlets receive items with sufficient remaining shelf life. -

POS at outlets

Sales at outlets flow back into Odoo, updating stock and feeding into planning for the next production cycle.

This tightens control over waste and availability and supports smarter menu and assortment decisions.

How Odoo Compares to Competitors

When compared to other ERP solutions, Odoo stands out for its ease of use, versatility, and affordability. Unlike many rivals, Odoo has a flexible price strategy that allows organizations to pay for only the modules they need.

Furthermore, its open-source nature allows firms to tweak the program to match their own requirements. What’s more? Odoo's user-friendly interface enables teams to adapt the system without substantial training, resulting in a simpler transition.

How Odoo Usually Compares With Other Erp Options In Food And Beverage

When you look at Odoo next to other ERP systems a few clear differences tend to show up.

| What you look at | Many traditional ERPs | Odoo for food and beverage |

|---|---|---|

| Balance between power and flexibility | Often very rigid and tightly built around one way of working or very open but heavy to customise and maintain. | Usually sits in the middle with enough structure for control and enough flexibility to match your processes. |

| Cost of ownership | Licence fees and implementation costs can be a major barrier, especially for mid-sized teams. | Entry point is often more accessible, and you can scale features and users as your business grows. |

| User adoption inside your teams | Complex screens can slow adoption and push people back to spreadsheets and side tools. | Cleaner interface that feels familiar to most users, helping with training and day-to-day use. |

| Ecosystem and extensibility | Add-ons and local help can be limited or tied to a small number of vendors. | Large ecosystem of partners and community modules, making it easier to add integrations and niche features. |

How Uncanny Consulting Works With Food And Beverage Teams On Odoo

Choosing the right software is important, but how it is implemented matters just as much. A good system can feel painful if it is set up without understanding your reality.

At Uncanny Consulting, we focus on Odoo and have significant experience in food and beverage projects. Here is how we usually work with clients in this space.

Understanding your processes before touching the system

We begin with discovery and process mapping.

-

We talk with people across departments

This includes purchasing, warehouse, production, quality, sales, finance, and sometimes outlet teams. Everyone sees a different side of the same issues. -

We map current and desired flows

Together we look at how goods and information move today and how you would like them to move. This highlights gaps and opportunities for improvement.

This step ensures that the Odoo setup is shaped around your business rather than the other way around.

Designing an Odoo solution that fits your food and beverage reality

Once we understand your context, we design the Odoo solution.

-

Selecting the right modules and phasing

We decide which apps to implement first for quick impact and which to add later when the team is ready. -

Defining key structures

This includes how products are set up, how units of measure are managed, how lots and expiry are handled, and how recipes and routes should work. -

Planning reporting and dashboards

We clarify which numbers matter to your leadership and how they should appear in reports and dashboards inside Odoo.

The result is a clear design that everyone can understand and comment on before configuration begins.

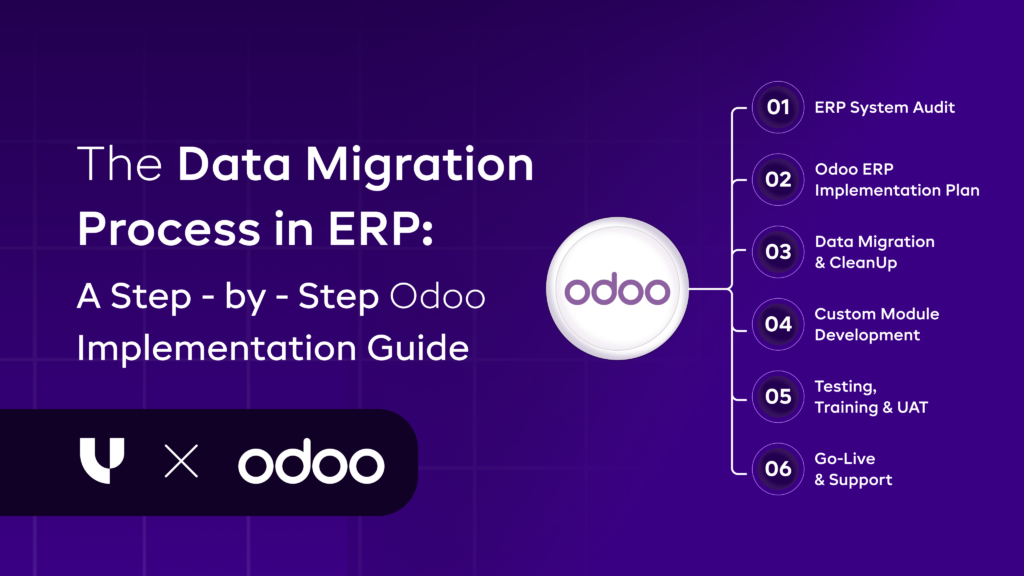

Implementing, migrating data, and integrating other tools

With the design agreed, we move into configuration and build.

-

Setting up Odoo according to the design

We configure modules, workflows, and security so that each team sees what they need and can perform their tasks reliably. -

Cleaning and migrating data

Product lists, customers, suppliers, opening stock, and open transactions are prepared and imported, so you begin from a realistic starting point. -

Connecting with external systems where needed

When relevant, we integrate Odoo with other tools such as ecommerce platforms, payment gateways, or third party logistics services.

This stage aims to deliver a working system that reflects your business rather than a generic demo.

Training your people and supporting real adoption

Technology only works if people feel comfortable using it.

-

Role-based training

We train each group on the parts of Odoo that matter for their daily work, using examples from your processes instead of generic scenarios. -

Clear guides and support

Simple reference material and responsive support help your team handle questions that arise as they practice.

The goal is not just to go live, but to reach a point where your team prefers using Odoo because it genuinely makes their work easier.

Staying with you as your business and system evolve

Food and beverage businesses rarely stand still. New products, partners, regulations, and channels appear over time.

-

Continuous improvement

After go live, we work with you to refine workflows, adjust configurations, and add new features as your needs change. -

Strategic support

We can help you plan how Odoo will support new locations, acquisitions, or changes to your business model.

With more than five years of Odoo experience, Uncanny Consulting aims to act as a long-term partner rather than a short-term project vendor.

What Odoo And Uncanny Can Achieve Together For Your Food And Beverage Business

Uncanny focuses on Odoo and has deep experience with food and beverage operations. When you work with our team, you get people who speak both languages: the language of recipes, batches, and shelf life, and the language of flow, configurations, and reports inside Odoo. We help you turn your real-world processes into a clear Odoo design, then configure the system so that traceability expiry control and cost visibility are built into daily work instead of added as extra chores.

If you are exploring Odoo for the first time or you already have a partial setup that does not really fit how you work, Uncanny can help you make sense of your options. The next step is simple: share how your business runs today and where you feel the most friction, and we can outline what an Odoo roadmap for your food or beverage business might look like and what kind of results you can realistically expect. Contact us now!

FAQs

Why should a food or beverage business use Odoo?

Odoo brings all core operations—inventory, production, sales, POS, purchasing, and finance—into one connected system. This removes the guesswork that happens with spreadsheets and disconnected tools. With real-time data and automated workflows, teams make faster, more confident decisions and reduce costly errors.

Can Odoo manage recipes and batches?

Yes. Odoo supports recipe versions, ingredient quantities, batch-wise manufacturing, and yield tracking in one place. This ensures that teams always follow the latest approved recipe and you maintain consistency even when ingredients, batch sizes, or processes change over time.

How does Odoo support traceability and food safety?

Odoo tracks every lot from supplier to production to customer delivery, making it easy to trace any issue instantly. Instead of searching through files during audits or recalls, you get complete backward and forward traceability with a few clicks. This keeps compliance smooth and protects your brand.

Can Odoo manage expiry and perishable stock?

Yes. Odoo records expiry dates, suggests FEFO picking, and alerts teams when items are nearing expiry. This helps avoid last-minute wastage, improves planning for fresh items, and reduces the hidden costs that come from overstocking or stockouts in perishable categories.

Does Odoo fit different F&B business models?

Odoo works for bakeries, breweries, cloud kitchens, packaged food brands, distributors, or retail chains because it adapts to different workflows. As you add new product lines or locations, the same system scales with you. This ensures your operations stay unified instead of splitting across multiple tools.

Which Odoo modules matter most for F&B?

Inventory, Manufacturing, POS, Purchase, Sales, Accounting, and Quality are the essential modules for F&B operations. Depending on the business, companies also add PLM for recipe control, HR for workforce management, or eCommerce for online orders. The stack grows as your operations grow.

How does Uncanny help with implementation?

We start by understanding your actual processes—recipes, batches, costing, stock flow, and compliance requirements—and then configure Odoo to match your real operations. We clean legacy data, set up practical workflows, train your team, and focus on adoption so the system works smoothly from day one.

How long does Odoo implementation take?

A basic F&B implementation typically takes 4–6 weeks, while multi-site or complex manufacturing setups take 12–16 weeks. Timelines depend on data readiness, customisation needs, and the number of modules, but we deliver early milestones so teams start using key features quickly.

Can Odoo integrate with POS, weighing scales, or delivery apps?

Yes. Odoo integrates with POS systems, kitchen display screens, weighing scales, online ordering platforms, and delivery partners. This ensures pricing, stock levels, and order information stay in sync across all channels, reducing manual adjustments and operational mistakes.

Is Odoo affordable for SMEs in F&B?

Yes. Odoo is modular, so SMEs can start with just the essential apps and expand later as the business grows. You avoid high upfront costs, get enterprise-level capabilities, and only pay for what you actually use—making it one of the most cost-effective ERPs for the F&B sector.

About Author