Top 8 ERPs for Food and Beverage Manufacturing in 2026

Published on January 21st 2026

Introduction

If you’re running a F&B business today, the ERP decision won’t stay optional for long.

At first, without an ERP, you keep telling yourself that everything is fine. Orders are coming in, and deliveries are being made on time. The team knows what to do. If something looks off, a team member steps in and fixes it. It works, mainly because people are filling the gaps.

Gradually, as you scale, those gaps become harder to ignore, and certain situations become more frequent. Like,

- Inventory looks right one week and wrong the next

- Inventory planning becomes challenging every month, where supply chain visibility matters

- Processes depend on a few people

- Customer queries are still unanswered

That’s the point when you start actually feeling there is a need for an ERP.

The search for the right ERP can become overwhelming, whether you’re comparing ERP options or trying to understand industry priorities. Every platform claims to be the best ERP for Food & Beverage Manufacturing, the best ERP for F&B, or the right ERP for cloud kitchens and franchise businesses.

We’ve seen that every ERP has its advantages. But we have seen several food businesses struggle later, not because they chose the wrong ERP, but because they chose the right ERP at the wrong stage.

With the ERP market for F&B business growing at a 8.2% CAGR from 2023 to 2030, it is necessary to address the most important queries you might have at this stage of your business.

“Which ERP to choose in 2026?”

This guide is designed to help you decide with context.

In this article, you’ll see:

- How do different ERPs fit different stages of F&B growth?

- Which systems suit cloud kitchens, manufacturers, and franchise-led models?

- Real patterns observed from our recent engagements with the F&B industry.

ERP Ecosystem for Food & Beverage Manufacturing (2026)

As you evaluate ERP options for 2026, one thing becomes clear quickly. Most ERPs are not competing on features alone. They are built for different stages of operational complexity.

As you evaluate ERP options for 2026, one thing becomes clear quickly. Most ERPs are not competing on features alone. They are built for different stages of operational complexity.

In the food and beverage industry, ERP systems generally fall into a few broad categories.

Early-stage structure tools

These systems help you move away from spreadsheets and manual tracking. They give you basic visibility into inventory, purchasing, and day-to-day operations. They work well when you’re operating from a single location or a small setup, and decisions are still centralized.

Flexible growth platforms

These ERPs are designed for businesses that are actively scaling. They support multiple locations, batch and expiry tracking, and workflows that continue to evolve. They work best when your processes are still taking shape, and you need room to adapt without locking into rigid structures too early.

Enterprise control systems

These platforms focus on standardization, reporting, and governance. They fit businesses where predictability, audit readiness, and internal controls matter more than flexibility. They work well when your processes are stable, and leadership is distributed across teams.

Compliance-first manufacturing ERPs

These systems are purpose-built for regulated food manufacturing environments. They prioritize batch traceability, quality control, recall readiness, and compliance reporting. They suit businesses where regulatory requirements actively shape how operations are run.

No category is inherently better than another. The real challenge is choosing an ERP that aligns with your business's direction in 2026, not just where it operates today.

Top 8 ERPs for Food & Beverage Manufacturing in 2026

There is no single “best” ERP for food and beverage manufacturing. The right fit depends on your business stage, operational complexity, and the level of structure your teams are ready to adopt.

And that’s how we have listed our top 8 ERPs.

1. ERPNext

ERPNext works best when your food business is still in its early operational stages.

It’s a practical option if you’re running a single kitchen, an early-stage cloud kitchen, or a small but growing F&B operation where visibility is critical.

Best suited for

Business Stage: Single kitchen or early cloud kitchen

At this stage, ERPNext helps you replace spreadsheets and manual tracking without adding operational overhead. You get basic visibility into inventory, purchases, and daily consumption, making it easier to track ingredients, control wastage, and understand costs without changing how your team works on the ground.

Business Stage: Small, growing operations

As order volumes increase, you begin standardizing how work is done. ERPNext helps you bring consistency across purchasing, stock movement, and basic reporting. It supports early process definition while keeping your system simple enough for founder-led decision-making and small teams.

Works well when

ERPNext works well when you’re operating from one location with a limited number of SKUs and relatively straightforward production or kitchen workflows. It fits businesses where decisions are still centralized, and the priority is gaining day-to-day visibility rather than enforcing tight controls.

You’ll see value when you need a clear view of inventory levels, purchase orders, and basic consumption patterns without introducing heavy planning logic or complex approvals.

Strengths

At this stage of growth, ERPNext’s strengths are its simplicity and accessibility. It gives you:

- Straightforward ingredient and stock tracking

- Low total cost of ownership

- Faster adoption by kitchen and operations teams

Because the system stays lightweight, your teams can start using it without extensive training or resistance.

Limitations

- Your multi-location visibility and centralized control become difficult

- Purchasing, stock movement, and reporting often need your manual workarounds

- Your production planning and batch handling remain basic

- Growing menus and demand planning may require your manual intervention

- Reporting lacks depth for your cross-functional decision-making

When to move on

You’ll typically start outgrowing ERPNext when:

- You add multiple kitchens or manufacturing units

- Centralized purchasing becomes necessary

- You need stronger reporting, controls, or planning capabilities

At that point, the challenge isn’t using ERPNext more efficiently. It’s that your business has moved into a different operational stage, which requires a more flexible and structured ERP.

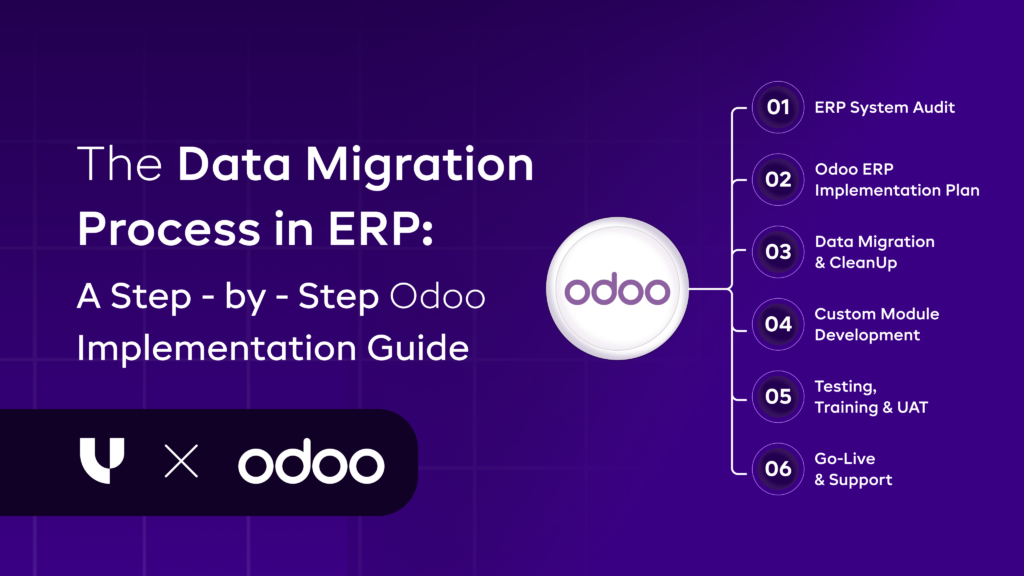

2. Odoo

Odoo serves businesses that have moved beyond basic visibility and are now facing scaling challenges. It works well when your food business is growing across locations, SKUs, or channels, and your processes need to evolve without being locked into rigid working structures too early.

It’s commonly used by food manufacturers, cloud kitchen groups, and multi-brand F&B businesses that need flexibility without losing control.

Best suited for

Business Stage: Growing operations

At this stage, Odoo helps you connect inventory, purchasing, production, and sales into a single flow. You can begin standardizing processes as order volumes, menus, and fulfillment models change.

Business Stage: Multi-kitchen or multi-unit setups

As you expand across locations, Odoo supports centralized visibility with local execution. You can manage stock across kitchens or plants, track batches and expiry dates, and implement structured workflows without disrupting day-to-day operations.

Business Stage: Franchise-led models (with governance)

For franchise or partner-led expansion, Odoo can support your governance through defined processes, approvals, and reporting, provided there is clear process ownership and implementation discipline.

Works well when

Odoo works well when your business is scaling, and operational complexity is increasing. You may be running multiple kitchens or manufacturing units, handling a wider SKU mix, or serving multiple sales channels.

You’ll see value when you need flexibility in workflows, stronger visibility across locations, and the ability to adjust processes as the business continues to evolve.

Strengths

Odoo’s strength lies in its flexibility. It offers:

- Manufacturing and inventory workflows suited to food operations

- Batch and expiry tracking across locations

- Support for multi-unit and multi-channel setups

- The ability to adapt processes as requirements change

With the right implementation, Odoo can scale alongside your business without forcing premature rigidity.

Limitations

- Extensive flexibility requires strong process definition and governance

- Customizations may increase maintenance and long-term complexity

- Small changes often require higher coordination as systems grow

- Compliance and audit needs need additional configuration or development

- Challenges surface as operations shift from growth to standardization

When to move on

You may start reassessing Odoo when:

- Compliance and audit requirements become a major priority

- You need consistent processes across the entire organization

- Reporting needs to be tightly controlled

At that point, the need shifts from flexibility to predictability and control.

3. SAP (S/4HANA and Business One)

SAP is well-suited for food and beverage businesses that have reached a stage where control, consistency, and governance matter more than flexibility.

It’s commonly used by large multi-unit operations and franchise-led businesses where processes are stable, reporting needs are rigorous, and leadership requires reliable, standardized data across the organization.

Best suited for

Business Stage: Large multi-unit operations

At this stage, SAP helps you standardize processes across kitchens, plants, or regions. It supports you with structured inventory, purchasing, and financial workflows that prioritize consistency and audit readiness.

Business Stage: Franchise-led F&B businesses

For franchise models, SAP supports governance through defined rules, controls, and reporting structures. It works best when your operational changes are limited and compliance expectations are clearly defined.

Works well when

SAP works well when your processes are well documented, growth is planned, and leaders expect consistent reporting across units.

It’s a strong fit for your F&B business when it needs precise financial control, traceability, and structured oversight at scale.

Strengths

SAP’s strengths lie in its reliability and control:

- Strong financial and inventory management

- Consistent reporting across units and regions

- Proven performance in large-scale environments

For businesses operating at scale, this consistency becomes a key advantage.

Limitations

- Designed for stability and control, which can limit flexibility

- Process changes require formal configuration and change management

- Longer implementation timelines and higher total cost of ownership

- Less suited for rapid experimentation or frequent workflow changes

- New products or operating models take longer to introduce

- Limitations surface when speed and adaptability still matter

When to move on (or not choose SAP)

SAP may not be the right fit when:

- You are still figuring out how your operations should work

- You need to move quickly and adjust workflows often

- Your teams are not prepared for structured governance

In those cases, the system can slow down your execution.

4. Salesforce (Always in a Supporting Role)

Salesforce is not a manufacturing ERP, but it is used to manage customer relationships, coordination, and visibility across partners and franchise networks. It provides leaders with a structured way to track interactions and performance without disrupting core operations.

Best suited for

Business Stage: Franchise-led and multi-outlet operations

At this stage, Salesforce helps you manage relationships across franchisees, distributors, and partners. It provides you with a centralized view of accounts, communication, and performance without disrupting operational systems.

Business Stage: Multi-brand or multi-channel businesses

When customer engagement, partner communication, and reporting become complex, Salesforce helps you bring structure to those interactions while your ERP handles manufacturing, inventory, and finance.

Works well when

Salesforce works well when coordination and visibility matter more than transactional processing. You’ll see value when you need:

- Clear oversight of franchise or partner activity

- Structured customer and account management

- Consistent reporting across regions or brands

It is most effective when integrated with an ERP that already manages inventory, production, and financial workflows.

Strengths

Salesforce’s strengths lie in coordination and insight.

- Strong CRM and partner management capabilities

- Clear visibility into franchise and customer performance

- Flexible reporting and dashboarding

- Reliable integration with ERP systems like Odoo or SAP

For business leaders, this visibility often supports better decision-making across distributed operations.

Limitations

- Not designed to run your core manufacturing or kitchen operations

- Cannot manage your inventory, production planning, or cost tracking independently

- Relies heavily on tight integration with your ERP system

- Additional cost and operational overhead as your user base grows

- Limitations surface when used as a primary system instead of a supporting layer

Best used as

Salesforce works best as a layer for tracking customers, partners, and performance. Your ERP should continue to handle inventory, production, and finance.

5. BatchMaster Manufacturing ERP

BatchMaster is built for your food and beverage businesses if compliance, traceability, and quality control are central to your daily operations.

It is suitable for F&B manufacturers operating in regulated environments that need an ERP designed to support audits, recalls, and strict batch tracking.

It’s commonly used when operational flexibility is no longer the priority and regulatory readiness is non-negotiable.

Best suited for

Business Stage: Compliance-driven food manufacturing

At this stage, BatchMaster helps you manage batch-level traceability, quality checks, and regulatory documentation as part of standard operations. It supports F&B manufacturers by integrating audit readiness and recall management into everyday workflows.

Works well when

BatchMaster works well when:

- Batch traceability is mandatory

- Quality control is embedded across production

- Regulatory audits are frequent

- Recall preparedness is a business requirement, not an exception

You’ll see value when compliance drives operational decisions.

Strengths

BatchMaster’s strengths lie in its food-specific focus.

- Deep batch and lot traceability

- Integrated quality and compliance workflows

- Strong recall readiness and audit support

- Explicitly designed for regulated food manufacturing environments

For businesses operating under strict regulatory frameworks, this specialization reduces risk.

Limitations

- Rigid batch and regulatory workflows limit your operational flexibility

- Your frequent process changes or experimentation are more complex to manage

- Customization beyond compliance requires additional effort and support

- New products or process variations take longer to introduce

- Limitations surface when flexibility and faster change cycles matter more than strict batch control

When to move away from BatchMaster

You may start reassessing BatchMaster when compliance is no longer the primary driver of daily operations.

This often shows up when:

- The business needs more flexibility to support new products or markets

- Processes change frequently and don’t fit rigid compliance workflows

- Enterprise-wide planning and reporting become more critical than batch-level control

At that point, the system still manages compliance well, but it may slow your business's ability to adapt.

6. Deacom ERP

Deacom is built for food and beverage manufacturers, where production discipline and quality control are at the center of operations. It fits your F&B business that needs its ERP to tightly integrate manufacturing, inventory, quality, and compliance into a single, controlled system.

It’s typically considered when operational maturity is high, and the likelihood of change is intentionally limited.

Best suited for

Business Stage: Mid-to-large food manufacturing operations

At this stage, Deacom helps you manage production, quality, and inventory within a unified structure. It supports manufacturers where decisions are driven by production accuracy, yield control, and compliance consistency.

Works well when

Deacom works well when:

- Production planning and execution are tightly managed

- Quality checks are embedded into manufacturing workflows

- Batch and lot tracking must stay consistent across the entire operation

- Compliance requirements are stable and well-defined

You’ll see value when your processes are already established and need to be enforced consistently.

Strengths

Deacom’s strengths come from its manufacturing-first design.

- End-to-end visibility across production and inventory

- Integrated quality and compliance management

- Strong batch and lot traceability

- A single system handling manufacturing, inventory, and financials

For f&b manufacturers with disciplined operations, this integration reduces operational gaps.

Limitations

- Integration requires a stable system with well-defined production processes

- Limited flexibility when your workflows or product mix are still evolving

- Your frequent workflow changes may need external support

- Limitations surface when experimentation matters more than consistency

When to move on from Deacom

You may start reassessing the value-added by Deacom when:

- Business models diversify beyond structured manufacturing

- Flexibility and rapid change become more important than consistency

- Operations expand into areas that don’t align well with tightly controlled workflows

Operations expand into areas that don’t align well with tightly controlled workflows

7. Aptean Food & Beverage ERP

Aptean Food & Beverage ERP is designed for manufacturers that need industry-specific workflows without building them from scratch. It is well-suited if your priority is achieving food-focused functionality, compliance readiness, and long-term stability over rapid operational change.

It’s typically considered when your manufacturing processes are well-defined and unlikely to change frequently.

Best suited for

Business Stage: Specialized food manufacturing operations

At this stage, Aptean supports you with established product lines and repeatable production methods. It works well when your batch handling, shelf-life control, and quality checks are consistent across production cycles.

Works well when

Aptean works well when:

- Batch and lot traceability must stay tightly linked to production

- Shelf-life and expiry need to be managed at the system level

- Quality checks are embedded into defined production steps

- Regulatory documentation is expected to be audit-ready by default

You’ll see value when operational consistency matters more.

Strengths

Aptean’s strengths come from its manufacturing focus:

- Built-in food production and quality workflows

- Compliance-ready design with minimal configuration

- Strong batch, lot, and expiry tracking

- Reduced reliance on custom development

For businesses with steady operations, this reduces implementation complexity.

Limitations

- Limited adaptability when your processes need frequent changes

- Customization options are more constrained than flexible ERPs

- New workflows or operating models often require workarounds

- Slower response when rapid operational changes are needed

- Limitations surface when flexibility and speed matter more than standardization

When you should move on from Aptean

You may start reassessing Aptean when:

- Operational models begin changing frequently

- New product lines require different workflows

- Flexibility becomes more important than standardization

At that point, the system’s stability may start to limit adaptability.

8. Sage X3

Sage X3 sits between flexible growth platforms and compliance-heavy manufacturing ERPs. It fits your food and beverage business if you need strong financial control and manufacturing integration without moving into fully rigid enterprise systems.

It’s often considered when operations are expanding across entities, regions, or product lines, and leaders need oversight without overengineering the system.

Best suited for

Business Stage: Growing to regulated manufacturing operations

At this stage, Sage X3 supports your business's growth while still giving you the flexibility to adjust operations. It works well when your manufacturing, inventory, and finance need to stay closely aligned as the business grows.

Works well when

Sage X3 works well when:

- Manufacturing and finance need tighter integration

- Manufacturing and finance need tighter integration

- Reporting and cost control are becoming leaders’ priorities

- Processes are defined but not entirely rigid

You’ll see value when visibility and control matter, with added flexibility.

Strengths

Sage X3’s strengths lie in balance:

- Strong finance and manufacturing integration

- Support for multi-entity and international operations

- Better control and reporting than lightweight ERPs

- More flexibility than heavy compliance-first systems

For businesses in transition, this balance can be a practical advantage.

Limitations

- Positioned between lightweight and enterprise-heavy ERP systems

- Requires careful implementation and strong process ownership

- It can become challenging to manage your smaller teams

- May fall short in your highly specialized compliance or governance needs

- Scaling across regions increases the ongoing support effort

- Limitations surface when extreme flexibility or strict compliance is required

When to switch from Sage X3

You may start reassessing Sage X3 when:

- Compliance and audit requirements become more specialized

- Enterprise-level governance is more crucial than operational flexibility

- Manufacturing complexity exceeds the system’s intended scope

At that point, a more specialized or enterprise-grade ERP may be required.

ERP Fit by Growth Stage (Quick View)

Choosing an ERP for your food and beverage business in 2026 is all about what fits your business. The table below summarizes how each ERP aligns with different stages of growth and operational priorities.

Want to start a project with us?

Empowering businesses to achieve greatness through strategic guidance and innovative solutions.

Book A Demo

Real-World F&B Use Cases

How Integrating Odoo Became Beneficial for Moyee Coffee?

We’ve applied this same stage-first approach while working with a food and beverage business from the Netherlands.

We’ve applied this same stage-first approach while working with a food and beverage business from the Netherlands.

While implementing Odoo for Moyee Coffee, the focus was never on forcing a predefined ERP structure. The priority was to understand how their sourcing, production, and traceability workflows actually operated across regions. The ERP was then shaped around those realities, ensuring that inventory visibility, batch tracking, and operational reporting supported the business without disrupting on-the-ground operations.

By aligning the system with how the business operated, Odoo became a support layer for growth. As operations evolved, Moyee Coffee's setup remained flexible enough to scale without requiring repeated rework.

This is the difference between selecting an ERP and implementing one with context.

How NAH Foods of the UK Brought Structure to Growing Operations with Odoo?

While working with NAH Foods, the biggest challenge was fragmentation.

While working with NAH Foods, the biggest challenge was fragmentation.

NAH Foods was operating with multiple disconnected tools to manage sales, inventory, procurement, and accounting. As order volumes increased and product lines expanded, visibility across operations became increasingly difficult. Inventory accuracy, purchase planning, and financial reconciliation required manual intervention, creating delays and operational challenges.

The ERP was then structured to bring transparency across inventory movement, purchasing cycles, and financial reporting without disrupting existing workflows. Instead of imposing rigid controls from the start, the Odoo-based ERP system was designed to stabilize day-to-day operations first and gradually introduce structure as volumes and complexity increased.

By aligning Odoo with NAH Foods’ real operating model, the ERP became a foundation for their scaling.

Final Thoughts: Choosing the Right ERP for Your F&B Business is About Timing

By the time you reach this point, one thing will be clear: there is no single “best” ERP for food and beverage manufacturing.

What matters far more is fit.

ERP decisions tend to fail not because the software selection is wrong, but because the system doesn’t match how the business actually operates at that moment.

Early-stage F&B operations need visibility. Those who are scaling operations need flexibility. Mature organizations need control. Regulated manufacturers need compliance built into daily workflows.

The right ERP supports how your business is working today and where it is heading next, without holding you back.

At Uncanny, this is precisely how we approach ERP implementations. As implementation partners for ERPNext, Odoo, SAP, and Salesforce, we do not believe in just selling the ERP. We consult first and ensure that the new ERP aligns with your operating model and growth plans.

Frequently Asked Questions

What is the best ERP for food and beverage manufacturing in 2026?

There is no single best ERP. The right choice depends on your business stage, operational complexity, and compliance needs.

Which ERP works best for cloud kitchens?

Cloud kitchens typically need an ERP that replaces spreadsheets and improves inventory visibility without adding complexity. Lightweight systems such as ERPNext and flexible platforms such as Odoo are commonly used at this stage.

What is the right ERP for franchise-led F&B businesses?

Franchise businesses need a combination of operational control and visibility. ERP systems such as Odoo and SAP are often paired with Salesforce to manage governance, reporting, and partner coordination.

Is there a good ERP for restaurant chains and multi-outlet setups?

Yes. Multi-outlet restaurant businesses benefit from ERPs that provide centralized visibility while enabling local execution. Odoo is often used for growth, while SAP is better suited to larger, more standardized operations.

Which ERP is suitable for cafes and small food brands?

Cafes and small food brands usually need basic inventory and purchasing visibility. Early-stage ERPs help streamline daily operations without forcing heavy processes too early.

About Author